How to Find the Best Custom Yoga Bra Manufacturer in China

- Share

- Issue Time

- Dec 19,2025

Summary

Manufacturing custom yoga bras in China, while potentially overwhelming, offers significant opportunities for brands. Key to navigating this landscape is understanding regional specializations, with Guangdong providing comprehensive supply chains for large-scale production and Fujian excelling in high-performance functional fabrics. The choice of material is paramount, with technical fabrics like polyester, nylon, and spandex blends being essential for moisture-wicking, four-way stretch, and dur

As someone deeply invested in the world of activewear, I've seen firsthand the transformative power of a well-made yoga bra. It's more than just a piece of clothing; it's a foundation for confidence, comfort, and peak performance. That's why, at AOLAFREE, we're dedicated to helping you find the perfect custom yoga bra manufacturer in China.

Navigating the landscape of Chinese manufacturers can feel overwhelming, but with the right knowledge and a clear vision, you can unlock incredible opportunities. Join me as I share insights and guide you through the process of securing a manufacturing partner that truly understands your brand's unique needs for custom yoga bras.

Key Takeaways

- Geographic Specialization is Key: China's activewear manufacturing is concentrated in specific regions. Guangdong and Fujian are premier hubs, with Guangdong known for large-scale production and comprehensive supply chains, and Fujian specializing in high-performance functional fabrics. Understanding these regional strengths helps you target your search for a qualified custom yoga bra manufacturer.

- Fabric Choice Defines Your Product: The foundation of a great yoga bra is its material. Technical fabrics like polyester, nylon, and spandex blends are essential for properties like moisture-wicking, four-way stretch, and durability. The decision between premium branded fabrics (e.g., LYCRA®) and high-quality generic alternatives will impact your cost, performance, and brand positioning.

- Clear Vision through Technical Packs: Whether you choose an OEM (your design) or ODM (factory's design) model, a detailed technical pack (tech pack) is non-negotiable. This document is your blueprint, containing everything from sketches and measurements to fabric specs, color codes, and stitching details. A clear tech pack is crucial for minimizing errors and bringing your vision to life with a custom yoga bra manufacturer.

- Compliance and Quality are Non-Negotiable: Selling in Western markets requires adherence to strict chemical and safety regulations like REACH (EU) and Prop 65 (California). Your chosen manufacturer must have experience with these standards. Furthermore, a robust quality control process, including performance testing for aspects like colorfastness, shrinkage, and stretch recovery, ensures the final product is durable and meets customer expectations.

- Vetting Partners is a Multi-Faceted Process: Look beyond the price. Evaluate a potential manufacturer's experience, specialization in activewear, and their existing product range. Ask for their quality control documentation and any sustainability certifications (like ISO 9001 or BSCI). At AOLAFREE, we pride ourselves on our transparent processes and proven Factory Strength, which serve as a benchmark for what a top-tier partner should offer.

- Building a Partnership, Not Just a Transaction: The ideal manufacturer is an extension of your brand. They should be a partner who understands your vision, offers design insights, and helps you navigate the complexities of production. Leveraging trade shows can be an excellent way to meet potential partners face-to-face, but building a long-term relationship based on trust and communication is what leads to sustained success. At AOLAFREE, our one-on-one service model is designed to foster exactly this kind of collaborative partnership.

Understanding the Ecosystem of a Custom Yoga Bra Manufacturer in China

To find the right manufacturing partner, you first need to understand the landscape. China’s manufacturing industry is not a monolith; it's a complex ecosystem of specialized hubs, intricate supply chains, and a vast range of material options. For activewear brands, knowing where to look and what to ask for is the first step toward success.

Geographic Hubs and Specialized Expertise

China's activewear manufacturing prowess is heavily concentrated in specific provinces, each with its own unique advantages. This geographic clustering creates powerful ecosystems where factories, fabric mills, and accessory suppliers operate in close proximity, fostering innovation and efficiency.

Why Fujian and Guangdong are Key for Your Custom Yoga Bra Manufacturer

When sourcing custom yoga bras, two provinces stand out: Guangdong and Fujian.

Guangdong Province: Home to cities like Guangzhou, Shenzhen, and Dongguan, Guangdong is a powerhouse for comprehensive apparel manufacturing and export. It boasts an incredibly mature and complete supply chain, offering access to a vast array of fabrics, trims, and advanced production technologies. Many well-established activewear manufacturers are located here, known for their ability to handle large-scale orders and their experience working with international brands. Guangzhou, in particular, is a major manufacturing hub with a well-established supply chain infrastructure that facilitates efficient production and logistics.

Fujian Province: Fujian, with cities like Jinjiang and Xiamen, has carved out a niche as a specialist in functional sportswear and high-performance fabrics. This region is renowned for its innovation in textile technology, especially for activewear like yoga bras that demand excellent stretch, moisture-wicking, and durability. As the home of our parent company, Jinjiang Well Rise Garment Co., Ltd., we at AOLAFREE leverage Fujian's expertise to create technically superior activewear.

Here’s a breakdown to help you choose:

| Feature | Guangdong Province | Fujian Province |

|---|---|---|

| Core Strength | Large-scale production, complete supply chains, export services | Specialization in functional fabrics, professional sportswear |

| Best For | Brands needing a wide variety of options and large order capabilities. | Brands focused on high-performance, technically advanced yoga wear. |

| Key Cities | Guangzhou, Dongguan, Shenzhen | Jinjiang, Xiamen |

| Ecosystem | Mature and comprehensive, from raw materials to logistics. | Highly specialized in textiles and innovative manufacturing. |

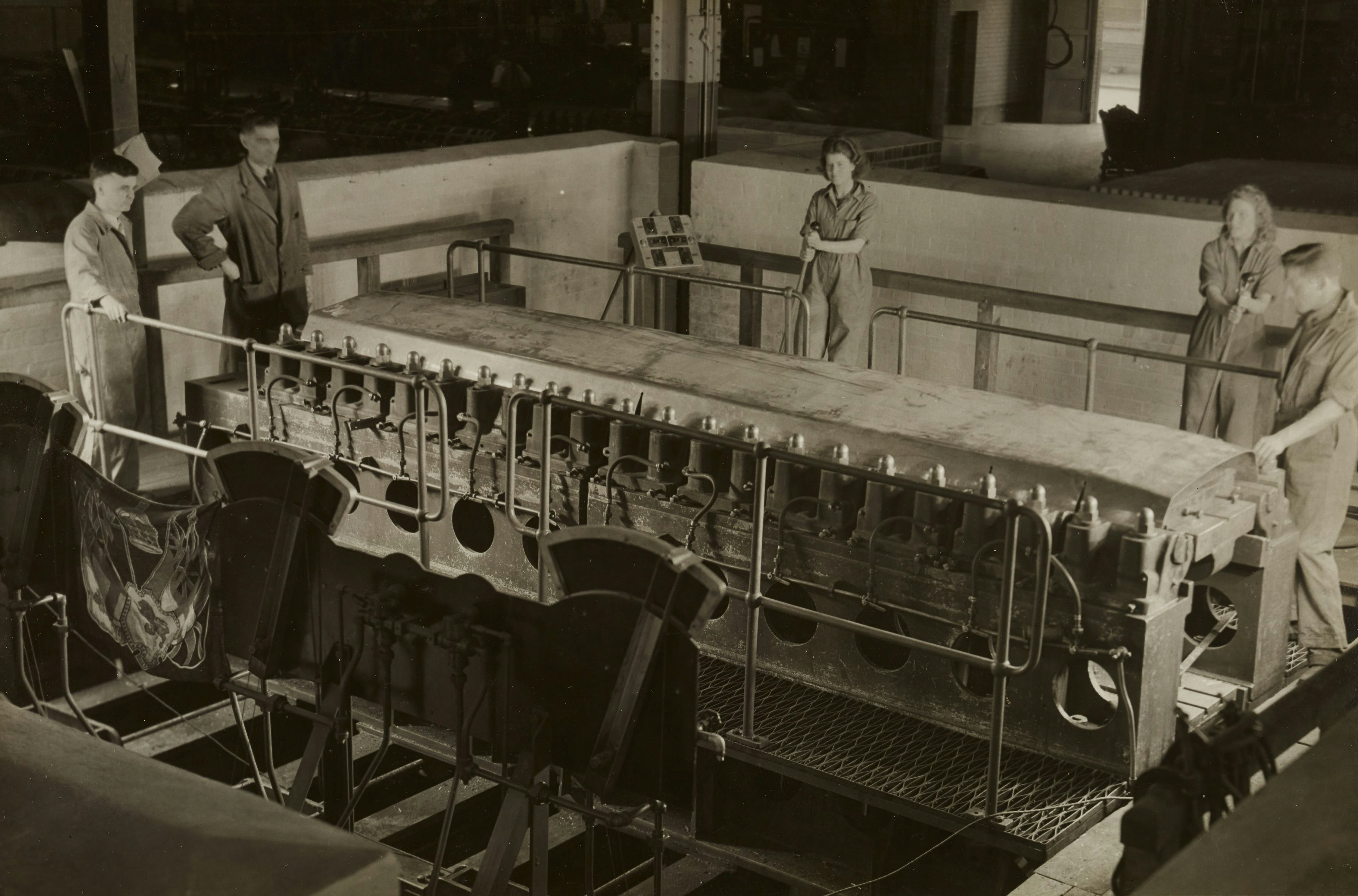

Alt text: A brightly lit factory floor with workers assembling custom yoga bras for a manufacturer in China.

Alt text: A brightly lit factory floor with workers assembling custom yoga bras for a manufacturer in China.

The Importance of Material Specifications for Your Custom Yoga Bra Manufacturer

The heart of any yoga bra is its fabric. The material choice dictates comfort, performance, durability, and even the final price point. A knowledgeable manufacturer will guide you, but it’s vital to have a foundational understanding of what you need.

Defining Technical Fabrics and Their Role for a Custom Yoga Bra Manufacturer

"Technical fabric" or "performance fabric" refers to textiles engineered with specific properties for athletic use. For a yoga bra, the key properties are:

- Moisture-Wicking: This is non-negotiable. Fabrics like polyester and nylon are excellent at pulling sweat away from the skin to the fabric's surface, where it can evaporate. This keeps the wearer dry and comfortable during intense practices.

- Four-Way Stretch: A yoga bra must move with the body like a second skin. Fabrics blended with spandex (also known as elastane or its brand name, Lycra) provide stretch both crosswise and lengthwise, allowing for a full range of motion without restriction. This elasticity is crucial for both comfort and maintaining the garment's shape.

- Breathability: The fabric must allow air to circulate, preventing overheating. While many synthetics are less breathable than cotton, modern performance knits are constructed to enhance airflow.

- Durability: The fabric needs to withstand repeated stretching, washing, and friction without pilling or losing its shape. High-quality nylon and polyester blends are known for their resilience.

Common fabric blends you'll encounter for yoga bras are Polyester/Spandex and Nylon/Spandex. Nylon is often praised for its soft, smooth feel and durability, while polyester is a workhorse for its excellent moisture management.

Navigating Branded vs. Generic Fabrics with Your Custom Yoga Bra Manufacturer

One of the key decisions you'll make is whether to use a well-known branded performance fabric or a high-quality "generic" or "unbranded" alternative.

Branded Fabrics (e.g., LYCRA®, Supplex®, TENCEL™):

- Pros: Using a famous brand like LYCRA® offers instant recognition of quality and performance. The LYCRA Company, for instance, engineers fibers for specific applications like LYCRA® SPORT for optimized stretch and recovery. This provides a marketing advantage and a guarantee of consistent quality and durability.

- Cons: The primary drawback is cost. Branded fibers are significantly more expensive, which will increase your final product price.

Generic/Unbranded Fabrics:

- Pros: High-quality generic spandex and nylon can offer performance nearly identical to their branded counterparts at a much lower cost. This allows for more competitive pricing or higher profit margins. A good manufacturer will have access to reliable mills that produce excellent unbranded technical fabrics.

- Cons: The quality can be inconsistent. It's crucial to work with a trustworthy manufacturer who thoroughly vets their fabric suppliers. You also lose the marketing cachet that comes with a recognizable ingredient brand.

What's the difference between Spandex, Elastane, and Lycra? They are essentially the same thing. Spandex is the generic term used in North America for a polyether-polyurea copolymer fiber. Elastane is the term used in most of the rest of the world. LYCRA® is simply the most famous brand name of spandex, owned by The LYCRA Company.

Ultimately, the choice depends on your brand's positioning. A premium, high-performance brand might find the investment in LYCRA® worthwhile, while a brand focused on accessibility and value can achieve fantastic results with the right generic fabrics. The key is to request samples and perform your own testing.

Crafting Your Vision: Design and Technical Packaging with a Custom Yoga Bra Manufacturer in China

With a solid understanding of the manufacturing landscape, it's time to translate your creative vision into a concrete plan. This stage is about clear communication and technical precision. How you prepare and present your designs will directly impact the success of your partnership with a custom yoga bra manufacturer.

OEM vs. ODM: What Fits Your Custom Yoga Bra Manufacturer Needs?

In the world of manufacturing, you'll constantly encounter two acronyms: OEM and ODM. Understanding the difference is crucial to defining your business model and finding the right partner.

OEM (Original Equipment Manufacturer): This is the path for brands with a unique design vision. In an OEM model, you provide the manufacturer with a complete design, including all specifications, patterns, and material requirements. The manufacturer’s role is purely to execute your vision.

- Best for: Brands with in-house design capabilities or a highly specific, unique product idea.

- Pros: Complete creative control and 100% product exclusivity.

- Cons: Requires a significant upfront investment in design and development, and often involves higher Minimum Order Quantities (MOQs).

ODM (Original Design Manufacturer): In this model, you select from designs that the manufacturer has already developed. You can then customize these existing products with your own branding, colors, and minor modifications.

- Best for: Startups, brands looking for a quick market entry, or companies wanting to test a new product line with minimal risk.

- Pros: Much faster and more cost-effective, as the design andinitial prototyping are already done. MOQs are typically lower.

- Cons: The core design is not exclusive to your brand, and customization options are limited.

Many successful brands actually start with an ODM model to get their footing and then transition to OEM as they grow and solidify their brand identity. As a versatile partner, AOLAFREE excels in both, offering one-on-one service to guide you whether you have a finished design or need assistance developing a new concept. Our innovative design team can help you navigate either path successfully.

Providing Clear Design Assets to Your Custom Yoga Bra Manufacturer

Whether you choose OEM or a customized ODM path, providing clear and detailed information is the single most important thing you can do to ensure you get the product you want. This is accomplished through a Technical Pack, or "Tech Pack."

A tech pack is the comprehensive blueprint for your yoga bra. It leaves no room for interpretation and should include:

- Technical Sketches: Flat drawings of the front, back, and sides of the bra.

- Bill of Materials (BOM): A complete list of all materials needed, including main fabric, lining, thread, elastic bands, pads, and any hardware. Specify fabric composition, weight (GSM), and color (using Pantone codes for accuracy).

- Graded Spec Sheet: A table of measurements for all key points of the bra across your entire size range (e.g., S, M, L, XL).

- Construction Details: Instructions on how seams should be stitched (e.g., flatlock seams for comfort), where labels should be placed, and any other assembly notes.

- Labeling and Packaging: Designs and placement for the main brand label, care label, and hangtags, as well as instructions for folding and bagging the final product.

Alt text: A sample tech pack showing technical sketches, material specifications, and measurement charts for a custom yoga bra.

Alt text: A sample tech pack showing technical sketches, material specifications, and measurement charts for a custom yoga bra.

A thorough tech pack minimizes misunderstandings, reduces the number of sample revisions needed, and protects both you and the manufacturer.

Ensuring Compliance and Quality with Your Custom Yoga Bra Manufacturer

Creating a beautiful design is only half the battle. Your product must also be safe, high-quality, and legally compliant in your target markets. A reputable manufacturer will be your partner in navigating these critical requirements.

Understanding Regulations (REACH, CA Prop 65, FHSA) with Your Custom Yoga Bra Manufacturer

When selling apparel in North America and Europe, you must comply with strict regulations regarding chemical substances. Your manufacturer must be aware of and able to meet these standards.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): This is a European Union regulation that restricts the use of certain hazardous chemicals in all imported products. A manufacturer familiar with REACH will ensure that the dyes and finishes used in your yoga bras are compliant.

- California Proposition 65 (Prop 65): This California law requires businesses to provide warnings to consumers about significant exposure to any of the 900+ chemicals that the state has listed as causing cancer or reproductive toxicity. For apparel, this can include substances like lead in zippers or certain dyes. A manufacturer experienced with the US market, especially California, should be able to source compliant materials to avoid the need for warning labels.

- Federal Hazardous Substances Act (FHSA): The FHSA in the US requires precautionary labeling on any household products that contain hazardous substances. For textiles, this can cover things like certain chemical finishes or flame retardants, ensuring they are used safely and labeled appropriately if necessary.

The Role of Performance Testing in Partnering with a Custom Yoga Bra Manufacturer

Beyond chemical safety, physical performance testing ensures your yoga bras will stand up to real-world use. A good quality control process involves testing for:

- Colorfastness: Tests the fabric’s ability to retain its color when exposed to washing, sweat, and light. No one wants a bra that bleeds color onto their skin or other clothes.

- Shrinkage: Measures how much the garment shrinks after washing and drying, ensuring a consistent fit over time.

- Dimensional Stability: Assesses whether the fabric distorts or loses its shape after use and laundering.

- Pilling Resistance: Determines how resistant the fabric surface is to forming small balls of fiber ("pills") from friction.

- Stretch and Recovery: Crucial for a yoga bra, this tests the fabric’s ability to stretch to a certain point and then return to its original shape.

A professional manufacturer will have a standard quality control process that includes these tests. Don't hesitate to ask for their QC documentation and lab test reports for the fabrics they propose.

Evaluating Potential Partners: Finding the Right Custom Yoga Bra Manufacturer in China

You’ve defined your vision and technical needs. Now comes the critical task of finding and vetting the manufacturer who will become your partner. This process requires diligence, clear communication, and a focus on long-term value over short-term cost.

Key Considerations When Selecting Your Custom Yoga Bra Manufacturer

Choosing a manufacturer is one of the most important decisions you'll make for your brand. It’s crucial to look beyond the price per unit and evaluate their capabilities, reliability, and business practices holistically.

Assessing Experience and Product Range: What Your Custom Yoga Bra Manufacturer Can Offer

The first filter in your search should be specialization. You want a partner who lives and breathes activewear, not a generalist factory that makes t-shirts one day and yoga bras the next.

- Specialization in Activewear: A manufacturer that specializes in sportswear will have a deep understanding of technical fabrics, performance construction techniques (like flatlock seams), and the specific fit requirements for garments designed for movement.

- Product Range: Examine their existing product catalog. Do they produce a range of sports bras, leggings, and other athletic apparel that aligns with your brand’s aesthetic? This demonstrates their experience and technical capabilities.

- Experience with International Brands: A factory that has a track record of working with brands in your target market (e.g., North America, Europe) will already be familiar with international quality standards, compliance regulations, and shipping logistics.

- Production Capacity and MOQ: Inquire about their monthly production capacity and their Minimum Order Quantity (MOQ). You need a partner who can meet your volume needs as you scale, but who also offers a reasonable MOQ for your initial orders.

Assessing a manufacturer's Factory Strength is about verifying their claims. Look for evidence of a well-organized facility, modern machinery, and a skilled workforce. At AOLAFREE, we pride ourselves on our immense monthly production capacity, which ensures we can handle orders for both emerging startups and established global brands without compromising on delivery timelines.

Examining Quality Control and Sustainability Practices at a Custom Yoga Bra Manufacturer

A manufacturer's commitment to quality and ethical practices is a direct reflection of the quality of your final product and your brand's reputation.

Quality Control (QC): A reliable manufacturer should have a documented, multi-stage QC process. This isn't just a final check before shipping; it should be integrated throughout production:

- Incoming Material Inspection: Checking all fabrics and trims for defects before they enter the production line.

- In-Process Inspection: Monitoring quality during the cutting and sewing stages to catch errors early.

- Final Inspection: A thorough check of finished garments for measurements, stitching, defects, and proper labeling before they are packed. Ask for their QC manual and look for certifications like ISO 9001, which indicates a standardized approach to quality management.

Sustainability and Ethical Practices: Today's consumers are increasingly concerned with how and where their clothes are made. Partnering with a sustainable and ethical manufacturer can be a powerful brand differentiator.

- Environmental Sustainability: Look for factories that are making an effort to reduce their environmental impact. This could include using recycled materials (like rPET), implementing water-saving dyeing techniques, or being powered by renewable energy. Certifications like OEKO-TEX Standard 100 (ensuring fabrics are free of harmful substances), Global Recycled Standard (GRS), or Bluesign are strong indicators of environmental responsibility.

- Social & Ethical Compliance: A manufacturer's responsibility also extends to its workers. Look for social compliance audits like BSCI (Business Social Compliance Initiative) or SEDEX, which ensure fair wages, safe working conditions, and reasonable hours.

Spotlight on a Custom Yoga Bra Manufacturer: Jinjiang Well Rise Garment Co., Ltd.

Finding a partner that embodies all these qualities can be challenging, which is why we want to introduce ourselves. AOLAFREE is the brand and service face of Jinjiang Well Rise Garment Co., Ltd., a premier custom yoga bra manufacturer located in the heart of China’s sportswear hub, Fujian.

As a leading activewear manufacturer, we are more than just a factory; we are your strategic partner in production. Our philosophy is built on providing a seamless, professional experience for every client, from startups to globally recognized brands.

Why partner with AOLAFREE?

- Deep Specialization: We focus exclusively on high-quality activewear, including yoga bras, leggings, and fitness apparel. This specialization ensures every product is crafted with expertise.

- Proven Factory Strength: Our state-of-the-art facility is equipped with advanced machinery and managed by a team with decades of experience, allowing us to boast a massive monthly production capacity to support your brand's growth.

- Innovative One-on-One Service: We don't just take orders. We partner with you. Our dedicated team provides one-on-one service to guide you through design, material selection, and production, ensuring your vision is perfectly executed.

- Commitment to Quality & Ethics: We implement rigorous quality control at every stage and are committed to sustainable and ethical manufacturing practices.

To learn more about our history, our values, and our commitment to excellence, please visit our About Us page. We believe in building lasting relationships that help brands thrive.

Beyond Manufacturing: Trade Shows and Labeling for Your Custom Yoga Bra Manufacturer Partner

Once you've shortlisted or even chosen a manufacturer, the partnership extends beyond the factory floor. Engaging with the industry and ensuring your final product is retail-ready are the final pieces of the puzzle.

Leveraging Trade Fairs to Connect with a Custom Yoga Bra Manufacturer

Trade fairs are an invaluable resource for meeting potential manufacturing partners in person. They offer a unique opportunity to see and feel product samples, assess a company's professionalism, and have in-depth conversations that aren't always possible over email.

Some of the most important trade shows for sourcing textiles and apparel in China include:

- Canton Fair (China Import and Export Fair): Held twice a year in Guangzhou, this is one of the largest trade fairs in the world, featuring a massive "Textiles & Garments" section in its Third Phase. It's an excellent place to meet a wide variety of manufacturers, from large-scale factories to specialized producers. Recent fairs have seen a huge increase in international buyers, highlighting its global importance.

- Intertextile Shanghai Apparel Fabrics: This is a leading global trade fair focused specifically on apparel fabrics and accessories. While it's more for sourcing materials, many fabric exhibitors are divisions of large garment manufacturers, making it a great place for networking and discovering innovation in performance textiles.

Attending a fair allows you to efficiently compare dozens of potential suppliers in a few days. You can gauge their expertise, see their latest innovations firsthand, and build personal relationships—a key ingredient for a successful long-term partnership.

Alt text: A bustling exhibition hall at the Canton Fair with buyers interacting with sportswear manufacturer booths.

Alt text: A bustling exhibition hall at the Canton Fair with buyers interacting with sportswear manufacturer booths.

Meeting Labeling Requirements with Your Custom Yoga Bra Manufacturer

Your product isn't ready to sell until it's properly labeled according to the laws of your target market. A good manufacturer will help ensure you meet these requirements. In the United States, the Federal Trade Commission (FTC) sets the rules. A standard garment label must include:

- Fiber Content: The generic fiber names and their percentages by weight must be listed in descending order (e.g., 87% Polyester, 13% Spandex). If a fiber makes up less than 5%, it should generally be listed as "other fiber".

- Country of Origin: The label must clearly state where the product was manufactured, for example, "Made in China". For products made in the USA from imported materials, specific wording is required.

- Manufacturer/Dealer Identity: The label must identify either the full company name of the manufacturer or importer, or their Registered Identification Number (RN), which is issued by the FTC.

- Care Instructions: The FTC's Care Labeling Rule mandates that garments have permanently attached labels with instructions for their care. This can be in the form of text or standardized symbols (ASTM D5489). Instructions should cover washing, drying, ironing, and bleaching. For example, a label for a yoga bra might say "Machine wash cold, lay flat to dry, do not bleach."

These labels must be securely attached and easily accessible to the consumer at the point of sale. Partnering with an experienced manufacturer like AOLAFREE ensures these details are handled correctly, saving you from potential legal issues and costly mistakes down the line.

Frequently Asked Questions (FAQ)

1. What is a realistic Minimum Order Quantity (MOQ) for custom yoga bras in China?

MOQ can vary significantly depending on the manufacturer and the complexity of your design. For fully custom OEM (Original Equipment Manufacturer) designs, factories often set MOQs between 500 to 1,000 pieces per style/color. This is because custom production requires creating unique patterns, sourcing specific fabrics, and setting up dedicated production lines, which is inefficient for smaller batches. However, for ODM (Original Design Manufacturer) models, where you're branding an existing factory design, MOQs can be much lower, sometimes as low as 100-300 pieces. At AOLAFREE, we understand the needs of both startups and established brands, offering flexible MOQ solutions and one-on-one consultations to find a production plan that works for you.

2. How long does the entire manufacturing process take, from design to delivery?

A typical timeline for a custom OEM order ranges from 90 to 180 days. This can be broken down as follows:

- Design & Tech Pack: 1-4 weeks (depends on your readiness).

- Sourcing & Sampling: 3-6 weeks. This includes creating the first prototype, shipping it to you for feedback, and making revisions. It can take multiple rounds to get the fit and details perfect. Timelines for ODM are often shorter as the base design is already complete.

- Bulk Production: 4-8 weeks. Once the final sample is approved, mass production begins. This timing depends on fabric availability and the factory's production schedule.

- Quality Control & Packing: 1 week.

- Shipping: 1-6 weeks. Sea freight is more economical but takes 4-6 weeks, while air freight is faster (about 1 week) but significantly more expensive. Clear communication and a detailed tech pack are the best ways to keep the process on schedule.

3. How do I protect my intellectual property (IP) and design when working with a Chinese manufacturer?

This is a valid concern for many brands. While no system is foolproof, you can take several effective steps to protect your IP:

- Work with reputable manufacturers: Established factories with a history of working with international brands are less likely to risk their reputation by stealing designs. Check for reviews, ask for references, and build a relationship of trust.

- Sign a China-Specific NNN Agreement: Before sharing any sensitive information, have the factory sign an NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement. Unlike a Western NDA, an NNN is specifically drafted for enforceability in China. It should be written in Mandarin, governed by Chinese law, and stamped with the company's official seal.

- Register Your Trademark in China: If you plan to sell your brand in China or are concerned about counterfeits, registering your trademark there is the single most effective protective measure. China operates on a "first-to-file" system, so it's crucial to register your brand name and logo before someone else does.

- Own Your Molds and Tooling: If your design requires custom molds or tools, ensure your contract specifies that you own them.

4. What are the main cost factors that determine the final price of a custom yoga bra?

The final "FOB" (Free on Board) price of your yoga bra is determined by several key factors:

- Fabric: This is typically the largest cost component. Branded fabrics like LYCRA® will be more expensive than high-quality generic alternatives. Fabric weight (GSM) and special finishes (e.g., anti-odor, UV protection) also affect the price.

- Order Quantity: The higher your order volume, the lower the price per unit. This is due to economies of scale in material purchasing and production line efficiency.

- Construction Complexity: A simple scoop-neck bra will cost less than a complex design with intricate strap details, mesh panels, multiple seams, and molded cups. Labor costs increase with complexity.

- Trims and Accessories: The cost of elastic bands, clasps, adjusters, removable pads, and custom-branded hardware all contribute to the final price.

- Printing and Labeling: Custom prints, heat transfers, and woven labels add to the cost compared to a solid-color garment with standard labels. A transparent manufacturer will provide you with a detailed cost breakdown.

Conclusion

Finding the ideal custom yoga bra manufacturer in China is a journey that, with AOLAFREE's guidance, can lead to incredible success for your brand. It's about meticulous planning, clear communication, and a strategic approach to partnership. From understanding the manufacturing ecosystems in Guangdong and Fujian to mastering the technical details of your design, every step is an investment in your product's quality and your brand's future.

Remember, the right manufacturer is more than just a supplier; they are an extension of your vision. We are confident that by following these steps, you will not only find a manufacturer but forge a lasting relationship that elevates your custom yoga bra line to new heights. If you're ready to take the next step and bring your vision to life with a partner committed to your success, we invite you to Contact Us. Let's build something amazing together.